Medical Device Manufacturing

Introduction

The field of healthcare has been revolutionized by technological advancements, and at the heart of these innovations lies medical device manufacturing. From basic instruments like thermometers to complex machines such as MRI scanners and robotic surgery systems, medical devices are essential to modern medicine. The process of manufacturing these tools demands exceptional precision, rigorous standards, and continuous innovation.

This article explores the entire landscape of Medical device manufacturing its technologies, challenges, and its significance in global healthcare.

What It Involves

Medical device manufacturing is the process of designing, producing, assembling, and testing tools and equipment used in healthcare. These devices can range from external aids like hearing aids and insulin pumps to implantable devices such as pacemakers and artificial joints.

The process involves:

- Product design and prototyping

- Material selection

- Precision machining or fabrication

- Assembly and packaging

- Sterilization and testing

- Regulatory approval

Each stage must meet strict medical and safety standards because the devices directly affect patient health.

Categories of Medical Devices

Medical devices are classified into three main categories:

- Class I (Low Risk) – Simple tools like bandages, surgical masks, or stethoscopes.

- Class II (Moderate Risk) – Devices such as blood pressure monitors, infusion pumps, and diagnostic kits.

- Class III (High Risk) – Devices that sustain or support life like heart valves, implantable defibrillators, and prosthetics.

The complexity increases as we move from Class I to Class III, requiring more sophisticated manufacturing processes and more rigorous regulatory compliance.

Precision and Technology

Modern medical device manufacturing relies heavily on advanced technologies to ensure accuracy and efficiency. Some of the most commonly used processes include:

- CNC Machining – For parts requiring tight tolerances and intricate shapes.

- Injection Molding – For mass-producing plastic components.

- 3D Printing (Additive Manufacturing) – For prototyping and creating custom implants.

- Laser Cutting and Welding – For precision assembly of small metal components.

- Micro-machining – For tiny parts used in devices like hearing aids and pacemakers.

Automation and robotics are also playing a growing role in streamlining production and improving consistency.

Material Considerations

Choosing the right material is critical for device functionality and safety. Titanium – Lightweight and biocompatible; used in implants.

- Stainless Steel – Durable and corrosion-resistant; ideal for surgical tools.

- Silicone – Flexible and hypoallergenic; used in catheters and tubing.

- PEEK and other medical-grade plastics – For disposable or non-metallic components.

- Ceramics and composites – Used in dental devices and bone replacement parts.

Material selection also depends on how the device will be used and whether it will be in contact with internal tissues or fluids.

Cleanroom Manufacturing

Cleanroom manufacturing ensures that contamination from particles, microbes, or chemicals is minimized. These environments are controlled for:

- Airborne particles

- Temperature and humidity

- Pressure and air filtration

- Worker hygiene and clothing

Maintaining a cleanroom is especially important for implantable and diagnostic devices where sterility is non-negotiable.

Quality Control and Testing

Errors are unacceptable since patient lives are at stake. Quality assurance involves:

- Visual inspections

- Dimensional and tolerance testing

- Functional testing

- Biocompatibility analysis

- Fatigue and stress testing

- Sterility validation

Devices must meet international standards like ISO 13485, as well as FDA and CE regulations depending on the target market.

Regulatory Compliance

To sell medical devices globally, manufacturers must comply with stringent regulations

United States: The FDA (Food and Drug Administration) governs medical devices under 21 CFR Part 820.

- Europe: CE marking is required under the EU Medical Device Regulation (MDR).

- Canada: Devices must meet Health Canada’s requirements.

- Japan: Overseen by the Pharmaceuticals and Medical Devices Agency (PMDA).

Regulatory approval often requires extensive clinical data, testing results, and manufacturing audits. Delays in approval can impact market launch timelines significantly.

See also: Mastering How to Solve Natural Logarithmic Equations

Innovations in the Industry

Innovation is transforming medical device manufacturing in many ways.

Notable advancements include:

- Smart devices that can monitor and transmit data in real time.

- Wearable technology for continuous health monitoring.

- Bioprinting, allowing the creation of tissue and even organs.

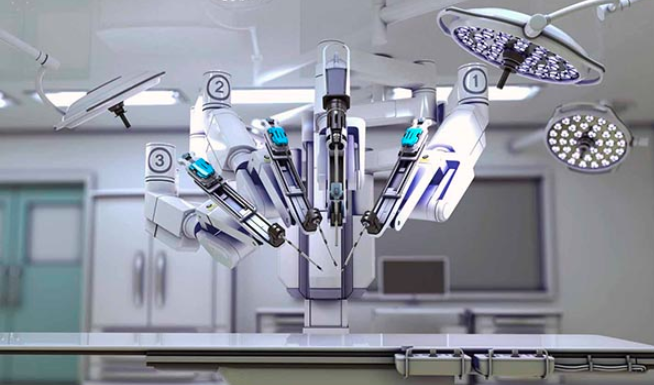

- AI-assisted diagnostics and robotics in surgical systems.

- Nanotechnology for targeted drug delivery devices.

These innovations not only enhance patient outcomes but also push the boundaries of what is possible in healthcare.

Sustainability in Manufacturing

With the rise of environmental consciousness, sustainable practices are becoming essential.

- Reducing single-use plastics through biodegradable alternatives.

- Using energy-efficient machines and renewable energy sources.

- Recycling materials and waste from production lines.

Outsourcing Trends

Many companies now outsource parts of their medical device manufacturing to specialized partners. Contract manufacturers offer:

- Cost savings on labor and materials

- Access to advanced machinery and expertise

- Faster production scalability

- Regulatory documentation support

Global Market Outlook

Aging populations, chronic diseases, and technological growth are driving demand. Key markets include:

- North America – The largest market, with high R&D investment.

- Europe – Known for strict regulations and high-quality manufacturing.

Conclusion

Medical device manufacturing is a complex, high-stakes industry that requires precision, innovation, and strict compliance with global standards. It plays a vital role in the delivery of effective and safe healthcare solutions to millions around the world. From design to delivery, every stage must be executed flawlessly to ensure that medical devices perform their life-saving functions without fail.

As the demand for better healthcare technologies rises, medical device manufacturing will continue to evolve—making healthcare more efficient, personalized, and accessible than ever before.