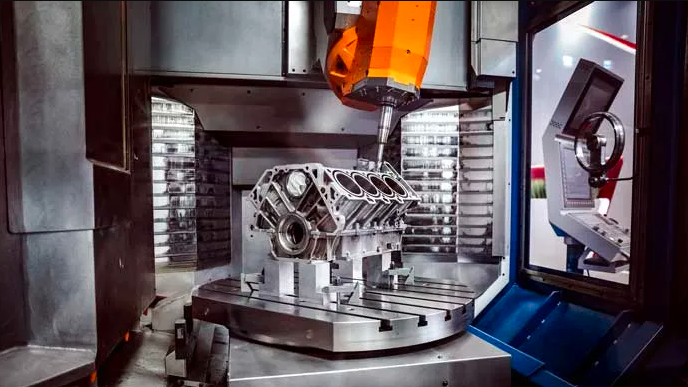

The Power of 5-Axis Milling Services

What Is 5-Axis Milling?

In modern manufacturing, precision and efficiency are essential, especially when dealing with complex components. One of the most advanced techniques that has transformed the industry is 5-axis milling. Unlike traditional 3-axis machining 5 axis milling services offer greater flexibility, enabling the creation of intricate designs. This process allows the cutting tool to approach the workpiece from nearly any angle, making it possible to create parts with complex shapes, tight tolerances, and superior surface finishes.

How Does 5-Axis Milling Work?

5-axis milling involves simultaneous movement across five different axes. These axes are typically defined as:

- X, Y, Z Axes: Representing linear movement in three directions—left/right, up/down, and forward/backward.

- A and B Axes: Representing rotational movements around the X and Y axes, respectively, allowing tilting and rotation of the workpiece.

By combining these five movements, 5-axis milling machines can achieve greater precision and handle more complex parts compared to 3-axis milling, which only moves along the X, Y, and Z axes. The added rotation gives the machine the ability to create more intricate features, often eliminating the need for multiple setups and tool changes.

Read also: Unlocking Potential with Capital-Supported Programs

Key Benefits of 5-Axis Milling Services

- Enhanced Precision and Accuracy

5-axis milling provides a higher degree of precision, allowing for tighter tolerances and more complex designs that are difficult to achieve with traditional 3-axis methods. - Reduced Setup Time

In traditional machining, complex parts often require repositioning the workpiece multiple times to access various surfaces. With 5-axis milling, the ability to move the part in all directions means the machine can access all surfaces in one setup, significantly reducing setup time and improving overall manufacturing efficiency. - Increased Design Flexibility

The versatility of 5-axis milling enables designers to produce parts that would be challenging to make with conventional machinery. This includes features like undercuts, intricate contours, and detailed geometries, which can’t be easily created with 3-axis or 4-axis machining. - Superior Surface Quality

The fine control over both the tool and workpiece allows for smoother finishes and superior surface quality. This is essential in industries where appearance and functionality are crucial, such as in medical devices and aerospace parts. It also reduces the need for additional post-processing, saving time and reducing costs. - Efficient Material Removal

With multi-directional cutting capabilities, 5-axis milling can optimize material removal rates. The machine can cut at more efficient angles, speeding up production while maintaining accuracy. This is especially important for machining tough materials like titanium and hardened steel.

Industries That Benefit from 5-Axis Milling

- Aerospace: Components such as turbine blades and engine casings, which require complex geometries, benefit from the precision and flexibility offered by 5-axis milling.

- Medical Devices: 5-axis milling is ideal for creating custom implants, prosthetics, and surgical instruments with high detail and tight tolerances, meeting the stringent requirements of the medical industry.

- Automotive: Automotive manufacturers use 5-axis milling to produce engine parts, transmission housings, and intricate interior components with reduced manufacturing time and high precision.

- Defense and Military: Components like missile housings and aircraft parts require absolute reliability and precision, which 5-axis milling services can deliver.

- Tooling and Die Making: Manufacturers of molds and tools, such as those used in plastic injection molding or die-casting, rely on 5-axis milling for their precision and speed.

Considerations When Choosing 5-Axis Milling Services

- Experience and Expertise

Select a provider with proven experience in machining the specific types of components you require. Their expertise ensures they can handle the complexity of your project and meet industry standards. - Equipment and Technology

The type of machinery used is critical. Ensure the service provider has advanced, up-to-date equipment capable of handling your materials and design requirements. - Quality Control

Rigorous quality control procedures are vital to ensure precision and adherence to standards. Providers with ISO certifications or similar quality systems are preferable. - Lead Time and Cost

Be sure to consider setup costs, material handling, and post-processing time to assess the total project cost.

The Future of 5-Axis Milling

As technology continues to evolve, 5-axis milling services are becoming even more advanced. The incorporation of automation, artificial intelligence, and machine learning allows for real-time optimization, further improving machining efficiency and precision. Additionally, innovations in cutting tools and materials are expanding the capabilities of 5-axis milling, making it a more affordable and accessible option for a wide range of industries.

Conclusion

5-axis milling services offer an advanced and efficient solution for producing complex, high-precision components in industries like aerospace, medical, automotive, and defense. The benefits of increased design flexibility, improved precision, reduced setup time, and superior surface finishes make it an invaluable tool for manufacturers. By choosing a provider with the right experience and technology, companies can maximize the potential of 5-axis milling to enhance their production processes and products.